Our Services

Tubestar, now with its wide range of offshore, Marine, Petro-Chemical inspection products, technical expertise (supported by our worldwide alliance / joint venture companies), is uniquely placed to meet your inspection requirements. All the information needed to make an informed decision on your inspection services can be found on this website. Please contact us if you have any further queries or require pricing information.

BHA Inspections:

- End area Inspections ( VTI / Black light/LPT / Dimensions )

- Centre wear pad inspections on HWDP ( Dimensional/Visual / MPI on upsets )

- MPI/LPT on Drill collar Slip & Elevator grooves

- MPI/LPT on upsets

- FLMPI /FL LPT( Optional )

- Dimensional inspection as per Spec like API RP-7G-2 & DS-1 or customer specification.

- Refacing Services

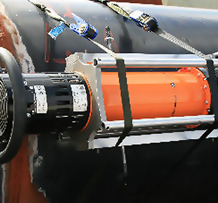

Dril Pipe Inspections & Services (Inspected to API and DS 1 requirements)

- Visual inspection on ful body

- EMI on ful body

- OD Gauging

- U.T. (Shear Wave) inspection on ful body

- U.T. Wal Thicknes measurement Heat checking inspection

- End area Inspections ( VTI / Black light / Dimensions )

- Visual Hard banding inspection if available

- 3 fe t end area Ultrasonic Inspections (Slip area MPI & Ultrasonic inspection)

- Refacing Services

- Straightening Services

- ID cleaning with rat ling

Casing and Tubing Inspections

Mill Inspections to include:

- Conformance to PO issued

- Witnessing online EMI inspections

- Witnessing all Calibration documentation

- Random spot wall thickness measurements

- Random Drift measurements

- Loading survey

- Identification

OLD and Retrieved OCTG

- Inspections to API Spec 5 CT/5B/5A5

- OD Blasting

- ID Cleaning

- Spot wall thickness measurements

- Grade Sorting

- EMI on body (Tubing )

- FLMPI using CDS units (Casing )

- Visual Thread inspection

- Drifting

- Black light inspections

- Hydraulic Pressure Testing

- Bucking Services

- Classification

Drops Objects Survey

- Survey Report - A compilation of assessments and specific equipment inspections resulting in the Dropped Object Survey.

- Fail Item List - A list of remedial actions required based on equipment inspections or surveys.

MPI and Eddy Current Inspections:

- MPI / Eddy Current on Drilling / Hoisting & Rotary Tools

- MPI / Eddy Current Fixed Lifting Equipment

- MPI / Eddy Current on Marine Equipment

- MPI / Eddy Current on Offshore Pedestal Cranes

- MPI / Eddy Current Inspection on Cantilevers

- MPI / Eddy Current Inspection on Miscellaneous Equipment

Cargo handling equipment (MPI onWelds and Load Testing)

- Inspection and recertification of Containers / Baskets and Pallets

- Proof load Testing Services

Thickness Gauging Inspections

- UT Thickness gauging on Tubulars

- UT Thickness gauging on High Pressure lines

- UT Thickness gauging on Mud tanks

- UT Thickness gauging on Rig Spud tanks

- UT Thickness gauging on Pressure Vessels

Radiograhy Inspection Services

- Industrial Radiography (Gamma Ray, Iridium, Selenium, Cobalt & X-Ray)

Cargo handling equipment (MPI onWelds and Load Testing)

- Inspection and recertification of Containers / Baskets and Pallets

- Proof load Testing Services

Derrick Inspections

- Inspections as per API RP 4G requirements

- Inspection of Mast/Derrick and accessories

- Sub Structures and accessories

- Crown Block Sheaves and Bearing inspection under RP 8B

- Eddy Current Inspection

Lifting Gear ( LEEA )

- Lifting Gear Inspections ( MPI / Load Testing / recertification ) as per PUWER (1998) and LOLER (1998)

- Inspection and certification of loose lifting equipment

- Fixed equipment Testing and certification

- Provision of Lifting Gear Register

- Eddy Current Inspection

Crane Inspection and load Testing

- Inspection as per Guidelines to API RP 2D

- MPI / Eddy Current Inspection

- Visual Inspection

- Load Testing

Rig Audit and acceptance

Auditing Services

Our offer covers the following management systems:

- OccupationalHealth & Safety (OHSAS18001)

- EnvironmentManagement System(ISO14001)

- QualityManagement System(ISO9001 & ISO/TS 29001)

- API RP 54 Occupational Safety for Oil & Gas well drilling

- PreventiveMaintenanceManagement System

- Leadership & Commitment

- Policy& Strategic Objectives

- Organization,Resources and Documentation

- Evaluation and RiskManagement

- Planning& Procedures

- Implementation& Monitoring

- Auditing& Reviewing

- Standard Condition Survey, Pre-hire Survey, Follow Up Survey

- Commissioning Services for New Rig

- Critical equipment audit and certification

- Audits are also provided at Contractors Operational Bases and Rig Sites

YardManagement Services

- Inspection and Maintenance of Tubular (OCTG) and related equipment

- Periodical Maintenance program – fixed in consultation with Operator and based on location

- Inventorymanagement ( Web Based Program )

- Ensuring proper identification and stacking of OCTG

- Preparation of OCTG for movement as per Drilling Plans

TUBESTAR - Innovative Reporting Solutions and Training

"TUBETRACK"

- Tubetrack is used for tracking the history of tubular and which can help client to monitor the condition of its tubular at any point of time.

Training Sessions include

- In-house training on NDT Techniques and their benefits

- Choosing the right Inspection methods / criteria

- DS-1 – Technical awareness School

- Practical training sessions for NDT training ( VT / PT / MPT / UT / RT / ECT )

- Customer specific training modules